Featured Case Studies

Northrop Grumman | Phased Array Antenna

Case Study

Northrop Grumman Corp. applied Model-Based Systems Engineering (MBSE) and Multidisciplinary Analysis and Optimization (MDAO) to the development of Phased Array Antenna Models to Improve Design Time and Quality

Northrop Grumman Corp. applied Model-Based Systems Engineering (MBSE) and Multidisciplinary Analysis and Optimization (MDAO) to the development of Phased Array Antenna Models to Improve Design Time and Quality The United...

Lockheed Martin Space | OSIRIS-REx

Case Study

Lockheed Martin Space utilizes integrated Model-Based Systems Engineering (MBSE) to simulate the mission trajectory of the OSIRIS-REx spacecraft

Lockheed Martin Space utilizes integrated Model-Based Systems Engineering (MBSE) to simulate the mission trajectory of the OSIRIS-REx spacecraft On September 5, 2016, an Atlas V rocketed from Cape Canaveral carrying...

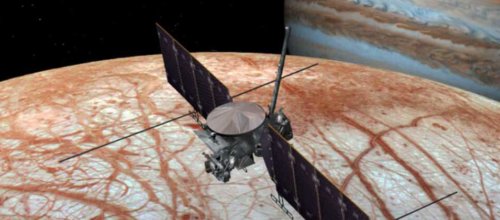

JPL

Case Study

Integration of Systems Models and Analytical Models Provides Order of Magnitude Time Savings

The National Aeronautics and Space Administration’s (NASA’s) Jet Propulsion Laboratory (JPL) is streamlining the space mission engineering process by integrating systems models that define the project architecture with the many...

Wind Farm – Stanford

Case Study

Multilevel Optimization Reduces Cost of Building Wind Farm by Almost $4 Million

The Bobcat Bluff Wind Project, located in Archer City, Texas consists of 100 GE 1.5 MW turbines capable of producing up to 150 MW of electrical power. Like nearly all...

e.deorbit

Case Study

Integrating Systems Modeling with Simulation Helps Ensure Robust Space Debris Removal Mission

The European Space Agency (ESA) is studying an active debris removal mission called e.deorbit which is intended to capture an ESA-owned derelict satellite in low orbit and safely crash it...

Centrifugal Compressor

Case Study

Analysis of Alternatives in ModelCenter Enables Rapid Selection of Optimal Centrifugal Compressor Configuration

Case Studies by Application

Webinar

Technical Papers

Phoenix Integration, Lockheed Martin

Authors: Hongman Kim, David Fried, Peter Menegay and Grant Soremekun, Christopher Oster

Authors: Nicolas Albarello et Hongman Kim