Lockheed Martin Space utilizes integrated Model-Based Systems Engineering (MBSE) to simulate the mission trajectory of the OSIRIS-REx spacecraft

Executive Summary

- Industry: Aerospace

- Products: ModelCenter MBSE , ModelCenter Integrate , ModelCenter Explore

- Applications: MBSE: Model Based Systems Engineering

Lockheed Martin Space utilizes integrated Model-Based Systems Engineering (MBSE) to simulate the mission trajectory of the OSIRIS-REx spacecraft

On September 5, 2016, an Atlas V rocketed from Cape Canaveral carrying the OSIRIS-REx spacecraft on a mission to discover the origin of our solar system by exploring the asteroid Bennu. Bennu may help us find answers to the questions central to the human experience: Where did we come from? What is our destiny?

The specific mission had the following objectives:

- Return and analyze a sample of Bennu’s surface

- Map the asteroid

- Document the sample site

- Measure the orbit deviation caused by non-gravitational forces (the Yarkovsky effect)

- Compare observations at the asteroid to ground-based observations

In October 2020, OSIRIS-REx conducted a “touch-and-go” maneuver to collect at least 60 grams, a far larger sample size than any other previous sample retrieval mission. On May 10, 2021, OSIRIS-REx fired its thrusters and heads on a 2.5-year course back to Earth.

The OSIRIS-REx mission was complex and daunting. Preparing for it required months of testing, modeling, and analyzing each step. This case study explores how Lockheed Martin planned for the mission using ModelCenter® and ModelCenter MBSE to enable Model-Based Systems Engineering (MBSE) for the success of the mission.

| Watch Webinar |

|

March 22, 2018 |

Background

OSIRIS-REx – Origins, Spectral Interpretation, Resource Identification, Security, Regolith Explorer – was designed by NASA to study the asteroid 101955 Bennu and conduct a sample-return mission. The mission’s primary objective was to land a spacecraft on the surface of Bennu, collect a sample of at least 2oz and as much as 4.4 lbs. in weight, and return with the sample intact.

Bennu is a near-Earth asteroid that approaches the planet approximately once every six years. Scientists are particularly interested in Bennu because only a few candidate asteroids are identified as rich in carbon-based molecules. This information may hold significant evidence relating to the origins of life on Earth and the possibility of life elsewhere within the solar system. The spacecraft collects other scientific data that will provide a more accurate survey of all asteroids and understand the chemistry and mineral content of “B” type asteroids. It is also measuring the ability of the sun’s radiation to effect slight changes in the asteroid’s orbit.

NASA contracted Lockheed Martin Space (LMS) to build the OSIRIS-REx spacecraft and provide mission operations. LMS also conducted simulations on the many parameters and constraints of the mission to ensure precise maneuvers and engagements.

Challenge

Rocket science is already complex, and that is only getting the launch vehicle off the ground. Now try landing a spacecraft on a moving, rotating, debris expelling object to collect a sample while maintaining spacecraft communication and preventing damage to sensors from solar radiation. That was the challenge of NASA’s OSIRIS-REx mission.

To prepare for the mission, Lockheed Martin Space (LMS) sequenced about one week of mission-time operations and simulated those operations on their testbed. Each test involved extensive manual operations, limiting the team’s ability to respond to change in requirements and mission parameters.

One week of simulated mission activity equaled one day of real-time simulation. For a ten-year mission, that would have meant mean months of simulating and analyzing data. Due to mission time constraints, the team was unable to simulate all possible variables and events. Any unplanned-for changes could have jeopardized the entire mission.

|

Mission Operation Challenges:

|

Customer Objectives:

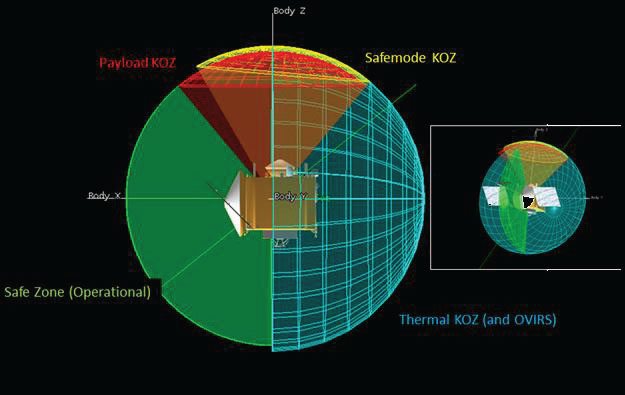

- Rapidly evaluate various trajectories for thermal constraint violations to identify the preferred mission trajectory

- Provide a quicker, more flexible approach for assessing geometry constraints during the early stages of mission planning

- Efficiently track variables during proposed OSIRIS REx trajectories

“Automating and integrating the simulation into this system model then allows the team to rapidly identify potential issues with changes to mission requirements, as well as perform continuous verification of requirements and mission design parameters throughout the lifecycle of the spacecraft... The overall improvement versus the original process was about a 7x speedup in turnaround time.”

Solution

|

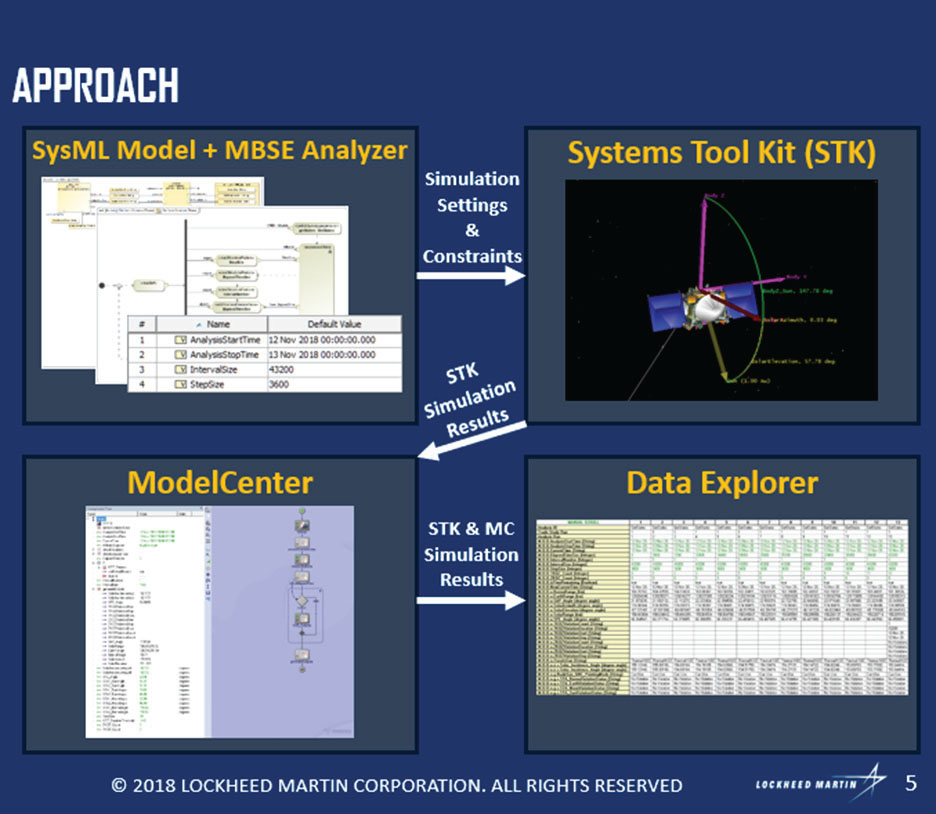

Lockheed Martin Space (LMS) developed a Model-Based Systems Engineering (MBSE) architecture to represent the spacecraft and the mission. To replicate and analyze the variables of space, they utilized mission simulation software. However, there was no bridge connecting the MBSE architecture to the simulations. Utilizing ModelCenter® MBSE, LMS was able to connect their MBSE models to the simulation tools. The system model captures mission and simulation parameters and thermal constraints. The parameter and constraints are time-stepped through a simulation that models the spacecraft’s orientation and trajectory concerning the Sun, Earth, Moon, and other bodies in the solar system. ModelCenter® will evaluate the results from the simulation to ensure adherence to the mission constraints. |

Solution Approach |

Benefit

Lockheed Martin Space developed a formal system architecture for both the mission and spacecraft that enabled them to quickly and accurately understand mission requirements and manage the relevant design parameters and their subsequent impact on various subsystems.

The team used ModelCenter® to automate and integrate the mission simulation with this system model. This allowed them to identify potential problems early in the design process, verify complex mission requirements throughout the lifecycle of the spacecraft, and respond to inevitable requirements changes.

LMS performed much more analysis than previous efforts, and their design tasks were accomplished seven times faster than their previous design process.